- Home

- Door Hardware

- Hinges

- Pivot Hinge

- Ives 7200 Series Pivots Fire Rated 3/4" Offset Intermediate Pivot 100 Pound Rating - 7226F INT

Ives 7200 Series Pivots Fire Rated 3/4" Offset Intermediate Pivot 100 Pound Rating - 7226F INT

Product Description

For more than 120 years IVES has produced a full line of premium quality building hardware and accessories that delivers application flexibility and superior value. The expansive portfolio includes hinges, pivots, flush bolts, strikes, door trim, pulls, protection plates, lock guards and many other hardware accessories.

Ives offers a wide range of Hinges and Pivots Multiple latches, catches and bolts to assure a door will stay closed when it is not in use.

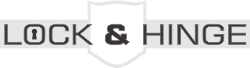

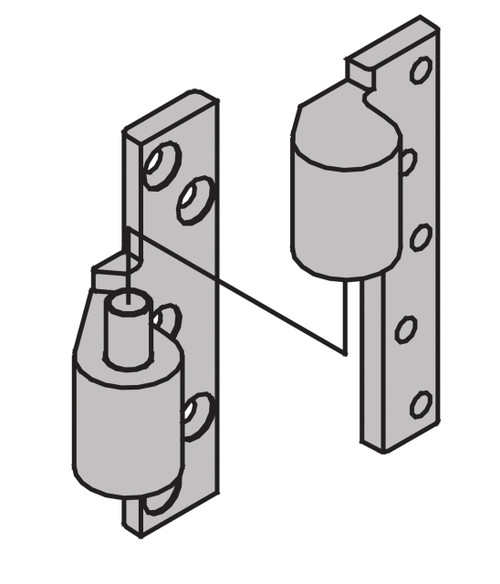

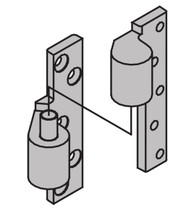

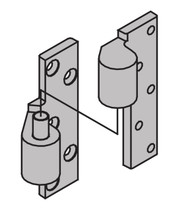

7215F-7226F-7227F INT

- Use with 7215F, 7226F or 7227F 3/4 Offset Pivot

- Handed

- Vertical adjustment 3/16", include positive locking

Hinges

Standard Weight - Plain Bearing

Standard Weight - Ball Bearing, Concealed Bearing

Heavy Weight - Ball Bearing, Concealed Bearing

- Weight of Door

- Frequency of use

- Frame

- Door Hardware

Always use ball bearing or concealed bearing hinges for doors with door closers and in all fire rated openings. Heavy weight doors and high frequency doors should use heavy weight ball bearing or concealed bearing hinges.

Guidelines for Hinge Material

- Interior door or non-corrosive area use: Plated or painted Steel

- Interior labeled door use: Plated or Painted Steel, Stainless Steel

- Interior door in corrosive area use: Stainless Steel , Brass, Bronze

- Exterior doors use: Stainless Steel, Brass, Bronze

NOTE: Standard pin material are: Brass Hinge – Steel Pin, Stainless Steel Hinge – Stainless Steel Pin, Steel Hinge – Steel Pin

- Door Width

- Door Thickness

- Weight

- Clearance

Pivots

The door rests on the bottom pivot in this application. This reduces the stress on the frame by distributing the weight of the door throughout the floor and structure. By taking advantage of the strength of the structure, this makes a pivot the ideal solution for your heavy doors. Center and pocket pivots also provide an aesthetic option for your opening.

Pivots

Pivots reduce the stress on the frame by distributing the weight of the door throughout the floor and structure. By taking advantage of the strength of the structure, this makes a pivot the ideal solution for your heavy doors. Center and pocket pivots also provide an aesthetic option for your opening.

Ives offers a complete line of 3/4" offset, 1-1/2" offset, center hung, intermediate and power transfer pivots with all exposed parts made of brass or stainless steel for maximum corrosion resistance. High strength brass and stainless steel forgings, and castings for rated and non-rated doors combined with precision bearings for smooth operation. Positive locking vertical adjustment mechanism allows the installer to precisely position the door and balance the load.

Designs and finishes

- 3/4” Offset – The center of the pivot point is offset from the face of the door by ¾”. This allows the door to swing almost 180 degrees if flush trim is on the door

- 1-1/2” Offset - The center of the pivot point is offset from the face of the door by 1 ½”. This allows the door to swing almost 180 degrees if you have a lever handle or pull on the door

- Intermediate – these are middle hinge style pivots for the middle of the door and are used in conjunction with a top and bottom pivot. This increases the door load capacity or fire rating requirements. NFPA 80, Section 3-3.8 requires intermediate pivot(s) on some fire door applications, consult catalog and factory for more information

- Center Hung – The pivot is centered within the door thickness of the door and installed directly above and below the door so there is not offset and thus center hung

Finishes:

- 600, USP – Primed for painting, Steel

- 605, US3 – Bright Brass, Brass

- 606, US4 – Satin Brass, Brass

- 612, US10 – Satin Bronze, Bronze

- 613, US10B – Oil Rubbed Dark Bronze, Bronze

- 625, US26 – Bright Chrome, Brass

- 626, US26D – Satin Chrome, Brass

- 706, SP4 -

- 691, SP10 – Light Bronze Painted Brass

- 689, SP28 – Aluminum Painted Brass

- 695, SP313 – Dark Bronze Painted Brass

- 622, SPBLK – Black Painted Brass

Base Material

Hinge Base material is key to preserving the life of a hinge

| Base Material | Ferrorus/Non-Ferrous | Application | For Use on Fire-Rated Doors |

|---|---|---|---|

| Steel | Ferrous/Susceptible to Rust | Interior Doors | Yes |

| Brass | Non-Ferrous/Rust Proof | Interior Doors in Corrosive Areas & Exterior Doors | No |

| Stainless Steel | Ferrous/Highly Resistant to Rust | Interior Doors in Corrosive Areas & Exterior Doors | Yes |

Special Pin Applications

- NRP- Non-Removable Pin

- TW4 - Four Wire

- TW8 - Eight Wire

- MON - Monitor

- TW4M - Four Wire with Monitor

- TW8M - Eight Wire with Monitor

| Build Type | Daily Usage | Hinge Type |

| High Frequency/Heavy Weight Door | ||

| Large Department Store Entrance | 5,000 | Heavy Weight |

| Hospital Corridor and Surgical Doors | 5,000 | Heavy Weight |

| Large Office Building Entrance | 4,000 | Heavy Weight |

| School Entrance | 1,250 | Heavy Weight |

| School Toilet Door | 1,250 | Heavy Weight |

| Office Stairwell | 500 | Heavy Weight |

| Office Building Toilet Door | 400 | Heavy Weight |

| Medium Frequency/Medium Weight Door | ||

| School Corridor Door | 100 | Standard Weight |

| Hospital Consultation Rooms | 100 | Standard Weight |

| Office Building Corridor Door | 80 | Standard Weight |

| Store Toilet Door | 60 | Standard Weight |

| Storage Room | 50 | Standard Weight |

| Low Frequency/Light Door | ||

| Residential Entrance | 30 | Plain Bearing |

| Interior Residential | 20 | Plain Bearing |

Grade 1: 2,500,000 Heavy Weight Ball & Concealed Bearing

Grade 2: 1,500,000 Standard Weight Ball & Concealed Bearing

Grade 3: 350,000 Light Weight Plain Bearing

| Door Thickness (in.) | Door Width (in.) | Hinge Height (in.) |

| 1 3/8” | Up to 32” | 3 1/2" |

| 1 3/8" | 32” to 37” | 4” |

| 1 3/4" | Up to 36” | 4 1/2” |

| 1 3/4" | 36” to 48” | 5” |

| 1 3/4" | Over 48” | 6” |

| 2” - 2 1/2” | Up to 42” | 5” heavy weight |

| 2” - 2 1/2” | Over 42” | 6” heavy weight |

Clearance Requirement

| Door Thickness | Clearance Needed | Hinge Open Width |

| 1 3/8 | 3/4 | 4 |

| 1 3/4 | 1 | 4 |

| 1 3/4 | 1 1/2 | 4 1/2 |

| 1 3/4 | 2 | 5 |

| 1 3/4 | 3 | 6 |

| 2 | 1 | 4 1/2 |

| 2 | 1 1/2 | 5 |

| 2 | 2 1/2 | 6 |

| 2 1/4 | 1 | 5 |

| 2 1/4 | 2 | 6 |

| 2 1/2 | 3/4 | 5 |

| 2 1/2 | 1 3/4 | 6 |

| 3 | 3/4 | 8 |

| 3 | 2 3/4 | 8 |

Guidelines for Number of Hinges

- Doors under 7'6" - 3 hinges

- Doors over 7'6" - 4 hinges

Complete line of 3/4" offset, 1-1/2" offset, center hung, intermediate and power transfer pivots with all exposed parts made of brass or stainless steel for maximum corrosion resistance.

- Handed

- Top, header mount

- Bottom, jamb mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 200 pounds

- Vertical adjustment range 3/16", with positive locking

7212V 3/4" Offset Pivot

- Handed

- Top, jamb mount

- Bottom, jamb mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 200 pounds

- Vertical adjustment range 3/16", with positive locking

7215/7215F 3/4" Offset Pivot

- Handed

- Top, header mount

- Bottom, jamb mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 500 pounds

- Vertical adjustment range 3/16", with positive locking

- WP - optional weather resistant bottom pivot is modified for improved corrosion resistance. Available in US26D (626) or US32D (630) only.

7222 3/4" Offset Pivot

- Handed

- Top, header mount

- Bottom, base plate mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 200 pounds

- Vertical adjustment range 3/16", with positive locking

7226/7226F 3/4" Offset Pivot

- Non-handed

- Top, header mount

- Bottom, base plate mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 600 pounds

- Vertical adjustment range 3/16", with positive locking

7227/7227F 3/4" Offset Pivot

- Non-handed

- Top, header mount

- Bottom, base plate mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 700 pounds

- Vertical adjustment range 3/16", with positive locking

7230F 3/4" Offset Pivot - Heavy Duty

- Non-Handed

- Top, header mount

- Bottom, base plate mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 1,000 pounds

- Vertical adjustment range 3/16", with positive locking

7237F 3/4" Offset Pivot - Heavy Duty

- Non-Handed

- Top, header mount

- Bottom, mortised cement case mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 1,750 pounds

- Vertical adjustment range 3/16", with positive locking

7244F 1 1/2" Offset Pivot - Heavy Duty

- Non-Handed

- Top, header mount

- Bottom, base mount

- Use with 1 3/4" minimum door thickness

- Maximum door load 400 pounds

- Vertical adjustment range 3/16", with positive locking

7245F 1 1/2" Offset Pivot - Heavy Duty

- Non-Handed

- Top, header mount

- Bottom, mortised cement case mount

- Use with 1 3/4" minimum door thickness, with 1/8" bevel in 2"

- Maximum door load 500 pounds

- Vertical adjustment range 3/16", with positive locking

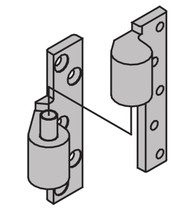

Intermediate Pivots

NFPA 80, Section 3-3.8 requires intermediate pivot on some fire door applications, consult factory. Use for door heights over 7'0" and one every 2'6" or . Use for door weight over the pivot set limit. One additional for every additional 100 pounds. Door thickness 1 3/4" mimumum with 1/8" bevel in 2".

7212-7212V-7222 INT

- Use with 7212, 7212V or 7222 3/4 Offset Pivot

- Handed

- Vertical adjustment 3/16", include positive locking

7215-7226-7227 INT

- Use with 7215, 7226 or 7227 3/4 Offset Pivot

- Handed

- Vertical adjustment 3/16", include positive locking

7215F-7226F-7227F INT

- Use with 7215F, 7226F or 7227F 3/4 Offset Pivot

- Handed

- Vertical adjustment 3/16", include positive locking

7230F-7237F INT

- Use with 7230F or 7237F 3/4 Offset Pivot

- Handed

- Vertical adjustment 3/16", include positive locking

7244F-7245F

- Use with 7244F or 7245F 1-1/2" Offset Pivot

- Handed

- Vertical adjustment 3/16", include positive locking

Pivots

7215PT-7226PT-7227PT Power Transfer Pivot

- Use with 7215, 7226 or 7227 3/4" Offset Pivots

- Four wires, 28 guage

- Optional 8 wire available

- Rated 50 VDC or VAC @ 3.5 amps. Continuous or 16 amps pulse, maximum pulse 400 milliseconds.

- Non-load bearing

- Use with 1-3/4" thick door mimimum, 1/8" bevel in 2"

7253 Center Hung Pivot

- Non-Handed

- Top, header mount

- Bottom, base plate mount

- Easy installation tilt on bearing and bearing pin

- Use with 1 3/4" minimum door thickness

- Adjustable floor to door clearance 3/16" to 3/4"

- Maximum door load 300 pounds

- Vertical adjustment range 3/16", with positive locking

7255 Center Hung Pivot

- Non-Handed

- Top, header mount

- Bottom, base plate mount

- Easy installation tilt on bearing and bearing pin

- Use with 1 3/4" minimum door thickness

- Adjustable floor to door clearance 3/16" to 3/4", consultant factory if greater than 3/4"

- Maximum door load 500 pounds

- Vertical adjustment range 3/16", with positive locking

7255J Center Hung Pivot

- Non-Handed

- Top, header mount

- Bottom, jamb mount

- Easy installation tilt on bearing and bearing pin

- Use with 1 3/4" minimum door thickness

- Adjustable floor to door clearance 3/16" to 3/4", consult factory if greater than 3/4"

- Maximum door load 500 pounds

- Vertical adjustment range 3/16", with positive locking

7256 Center Hung Pivot

- Non-Handed

- Top, header mount

- Bottom, base frame mount

- Easy installation tilt on bearing and bearing pin

- Use with 1 3/4" minimum door thickness

- Adjustable floor to door clearance 3/16" to 3/4", consult factory if greater than 3/4"

- Maximum door load 600 pounds

- Vertical adjustment range 3/16", with positive locking

7259 Center Hung Pivot

- Non-Handed

- Top, header mount

- Bottom, base frame mount

- Easy installation tilt on bearing and bearing pin

- Use with 2" minimum door thickness

- Adjustable floor to door clearance 3/16" to 3/4", consult factory if greater than 3/4"

- Maximum door load 1,000 pounds

- Vertical adjustment range 3/16", with positive locking

91105F, 91105F-PT Pocket Pivot/Hinge

- Non-handed

- All stainless steel construction.

- Allows door to open a full 90 degrees

- Full mortise

- 90 pound load bearing

- Use two for doors up to 7'0" and over 7'0" use three

- PT, Power Transfer version has four 28 guage wires. Rated 50 VOC or VAC @ 3.5 amps. Continuous or 16 amps pulse. Maximum pulse 400 milliseconds.

Loading... Please wait...

Loading... Please wait...